The Art of Waxing Wood

Share

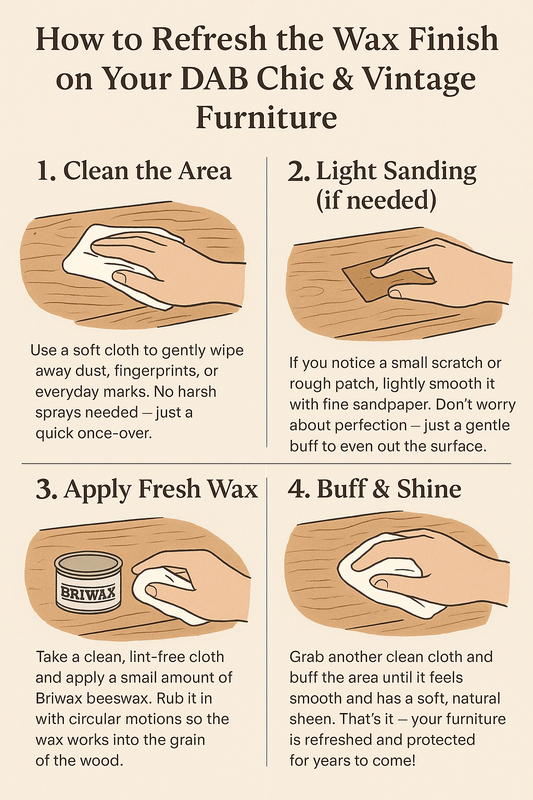

How we apply a beautiful beeswax finish to our furniture & interiors

One of the secrets of our unique style of interior wood products, is the stunning beeswax finish we use. We selected Briwax as our supplier, a top-quality beeswax blend available in a range of colours which creates a seductive rustic finish. Here, we will guide you through our process and explain why waxed furniture is a great choice over other finishing methods.

Preparing the Wood

Before applying beeswax, it’s crucial for us to prepare the wood properly. The process begins with a sanding session, all of the rough sawn cuts sanded to a semi-smooth surface, using a low grit sandpaper between 40 and 80 grit. Remove any splinters, take back edges and add some imperfections, this will enhance the natural look.

After sanding is complete, we brush away the dusty debris, ensuring nothing gets trapped underneath the protective wax.

Applying the finish

Now the wood is prepped, we can begin the waxing process. We start by selecting the correct shade to suit your home. Customers will choose from the colour chart we created, this lets them see exactly how the colour choice will look once applied to our wood. Our team uses chemical proof gloves to protect their hands and using a soft micro-fibre cloth, applies the wax in a circular motion, caressing it into the wood, ensuring a smooth, even application.

We allow the wax to soak into the wood for a few minutes and then begin to buff the surface with a clean micro-fibre cloth, removing excess wax and bringing through the texture in the wood. At this stage you will begin to see the character of the wood break out through the knots and grain, with any wax filled splits going from blemish to beauty. For a deep and durable finish, we add a second coat to the wood, repeat the first steps all over again.

Curing

After the second coat the waxed parts are placed on a racking system which allows maximum ventilation. Although it is touch dry after around 1 hour, we avoid any heavy handling for a couple of days and allow the wood to cure, this adds to the durability and allows any scent to fade. Over this time the woods finish will become harder and much more resilient.

Why Wax?

Why we choose beeswax? Waxing offers many advantages over other methods.

- Its eco friendly and unlike synthetic finishes, beeswax is a natural product, which protects your furniture and the environment.

- A luxury waxed finish gives wood an authentic, soft tone, enhancing the woods natural beauty. You can tell instantly that DABs furniture is real solid wood and the beeswax finish is the secret to this.

- Its low maintenance. Unlike other types of coating which require a full sanding a refinishing after years of use, waxed furniture can be easily touched up or recoated simply by adding more.

- Throughout the years, any bumps or scrapes will add to the furniture's allure, over the years this will add to the natural knots and splits which give the furniture its vibrant rustic hue.

At DAB, we agree that a high-quality beeswax finish is the perfect way finish generational, handmade furniture. To preserve your original finish, with each order we send out a DAB furniture care kit, to repair any accidental damage from moving home or unruly children!

If you're interested in our bespoke furniture with a timeless waxed finish, get in touch with us now!